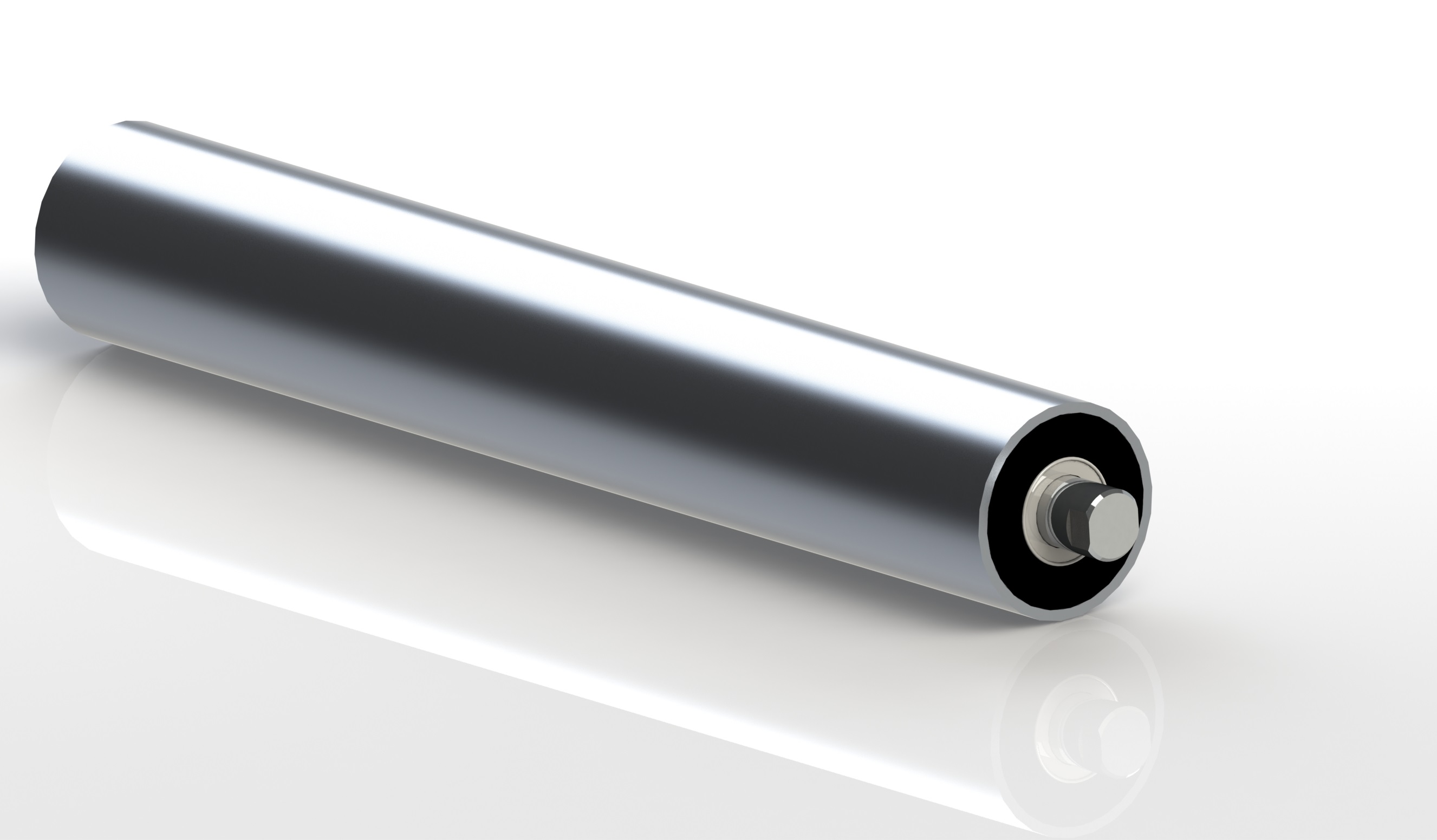

Belt Conveyors Rollers

These types of rollers are used for belt conveyors (at level; couple at 20° and triad at 30°), working also in bad environmental condition, in constant operation, with medium charge at high speed. Steel rollers, mounted on radial bearings 2RS. They are available in different tube diameters and different axis diameters according to the charge.

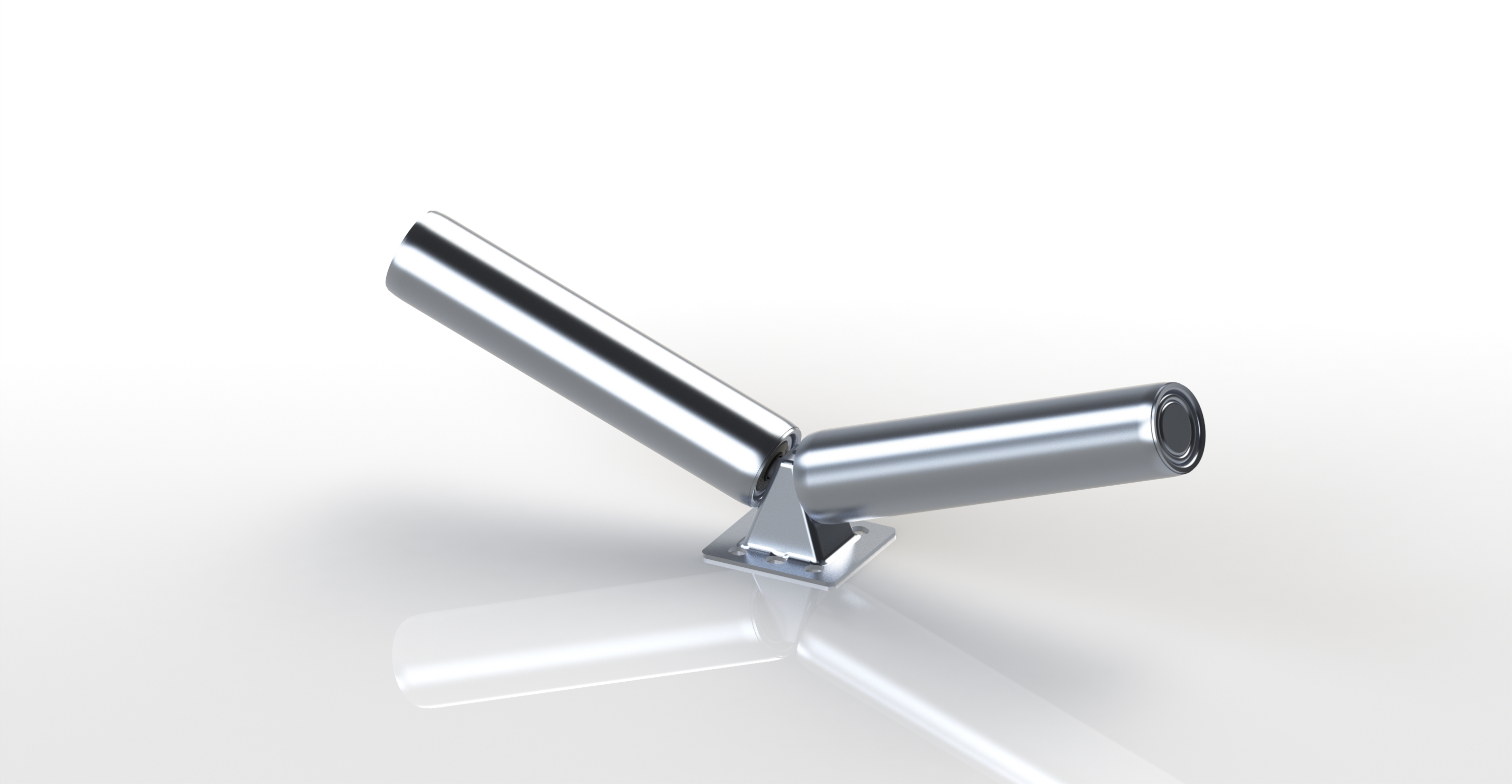

Couples of Rollers

They are used for belt conveyors, working in the most different environmental condition, with charges and medium operating speed. The sizes change for belt from mm 300 to mm 700 max. Rollers in steel for handling, mounted on bearings 2RS. The axis of rollers forming the couple is a single piece welded to the central support, composed by a single printed element in order to give the maxim rigidity to the structure. The minimum distance between rollers, and the particular support form allow the employ of extra flexible belt, removing the possible damage of the same for fiction. The superior ends of the couple are equipped of hermetic protection which allow lubricant, placed in phase of assembly, to keep constant over time the performance of roller, at temperatures included among -20° +90°. Axis Ø 15.

Triads of Rollers

They are used for bel conveyors. Realized in printed steel with rollers supports already welded, they allow to assembly the rollers unified. The rollers crossbars are normally supplied black, galvanized on demand, and with rollers axis perpendiculars to the direction of travel (reversible belts); in addition, according to fixing type, various elements can be supplied to connect the crossbars to the structures. The crossbars are of various sizes for belt from mm 500 up to mm 1400 max.

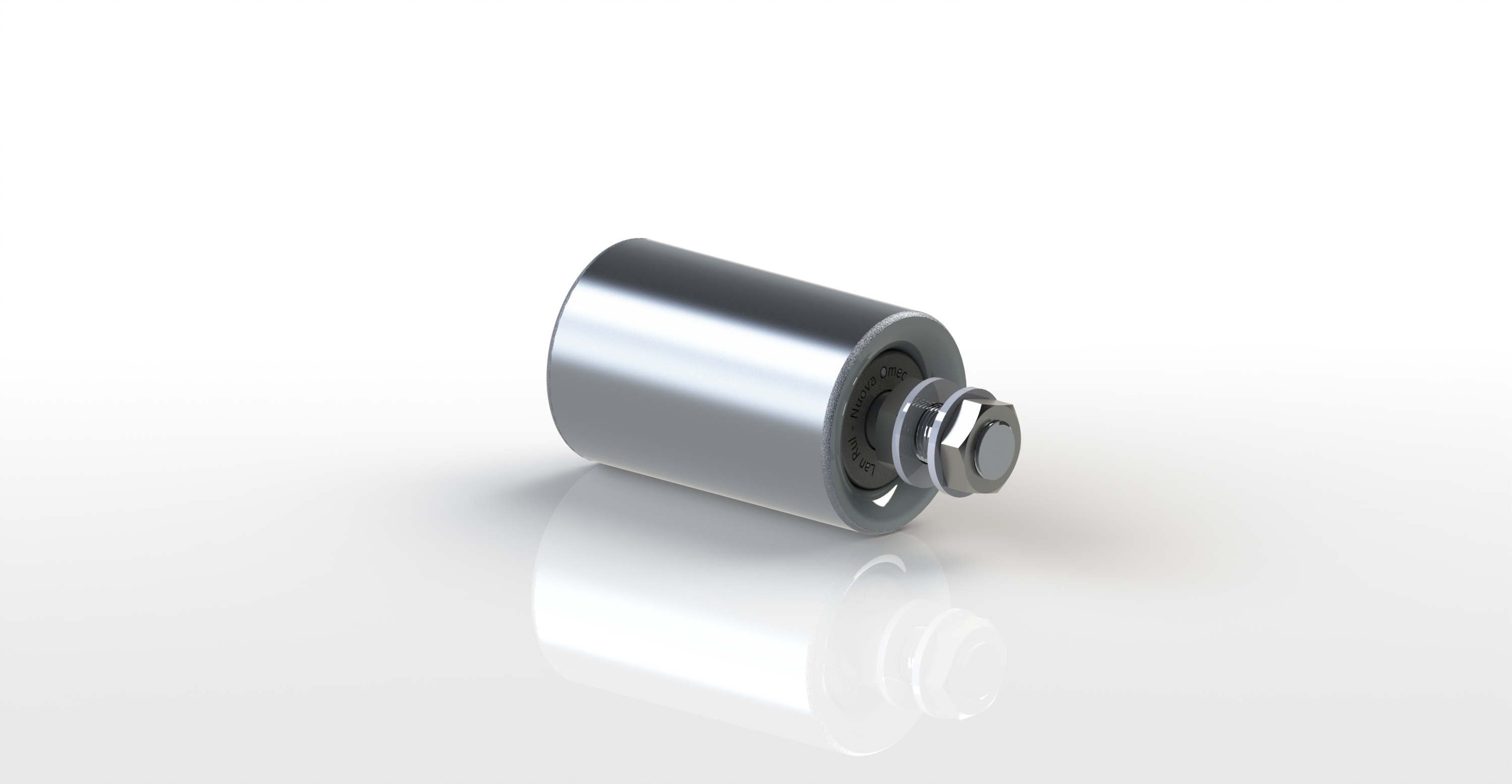

Guide belt Rollers

They are adopted in conveyors in order to contain the belt running within the expected line. Rollers in steel mounted on bearings 2RS. They are supplied in the version of permanent lubrication and with the possibility to be employed at the same temperatures of exercise of those provided for the LM series. They present at the superior end a hermetic protection. Guide belt rollers are fixed to conveyor sides through the threaded axis exit. They are available in different tubes and axis diameters, covered or with superficial treatment.

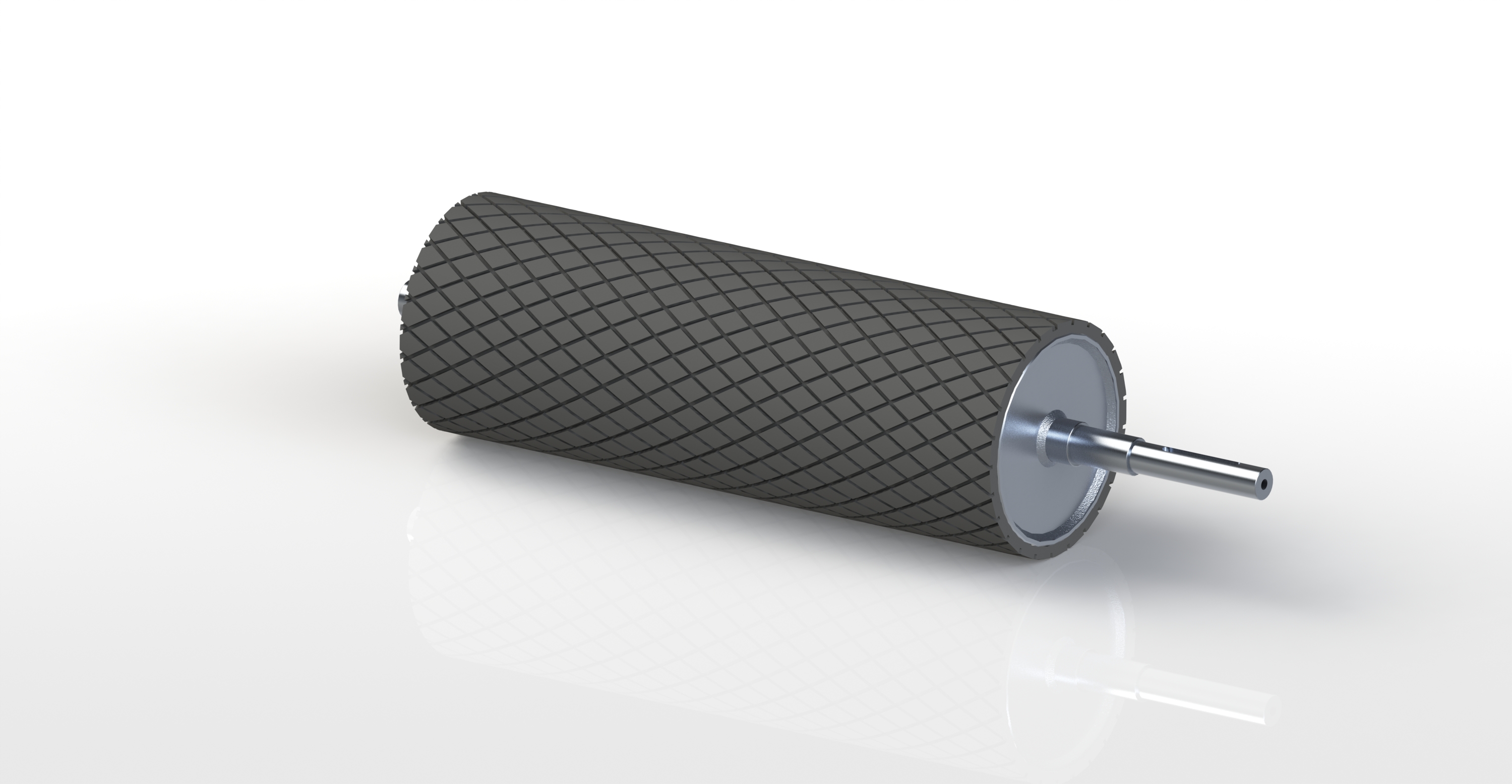

Rubbers Rollers Shock Absorbers

They are used for conveyors which present points of loading heavily concentrated. Rollers in steel mounted on a pinion of balls on radial rigid bearings. The forced assembly of the locked rings is carried out on the tube body, at the ends, from spacers and Seeger. Feature of rollers shock absorbers is the rubber ring profile. Once formed the group, an external uniform profile is realized in a way that it could offer to the belt a superficial of homogeneous box. In this way damages and local tensions are avoided, but not that expected during planning phase. The ring is in non-abrasive rubber and it is used for execution temperatures between -20° + 90°. The rings can be easily substituted. It is possible supplying rollers with a number of rings different from what illustrated. Available in different ring and axis diameters.

Drum

They are used for belt conveyors for towing or for returning the belt. They are built with monolithic structure. The external profile is rounded in order to assure a greater driving effect and a good guide of the belt. They are supplied by customer’s drawing, with rubber coverings on demand of the following types: rough, corrected, grooved.